Double tray

.png)

Cross section of a double tray horizontal bed deodoriser

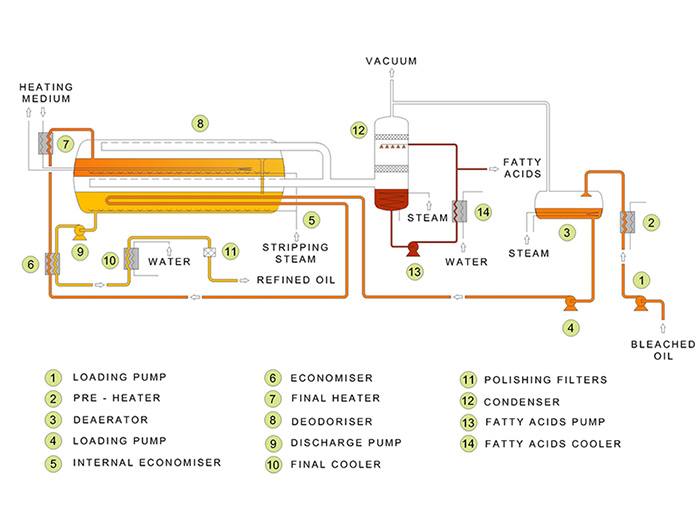

Process flow diagram of continuous horizontal shallow bed deodoriser

Description :

Pre-heated feedstock is deaerated in a splash plate type vacuum vessel after which it is heated under pressure in the lower tray vessel, in the coil assembly of a heat recovery. The heat is recovered from hot deodorised oil flowing through the vessel. The hot oil is further heated under pressure in an external heat exchanger for additional heat recovery. The oil is then brought to full processing temperature under pressure by high pressure steam in an external heater before entering the deodorising vessel.

The vessel is either a single or double pass cylinder (two levels or more) depending on capacity. The oil flows from one end to the other, past a series of vertical baffles, after which it discharges to the lower tray, another deodorising tray or a heat recovery level. During the passage, the oil is stripped, deodorised and heat bleached.

The temperature of the oil is maintained by steam heated tubes submerged in the oil. Stripping steam is injected by multiple pipe distributors running the length of the deodorising and heat recovery levels.

The deodorised oil is pre-cooled under vacuum by deaerated oil in the heat recovery level. It is further cooled under pressure by cold crude oil in an external heat exchanger for additional heat recovery.